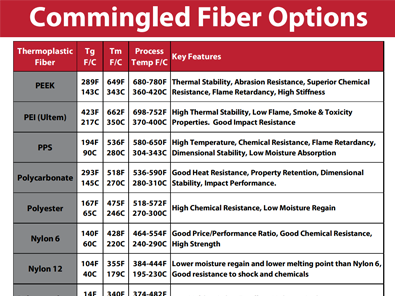

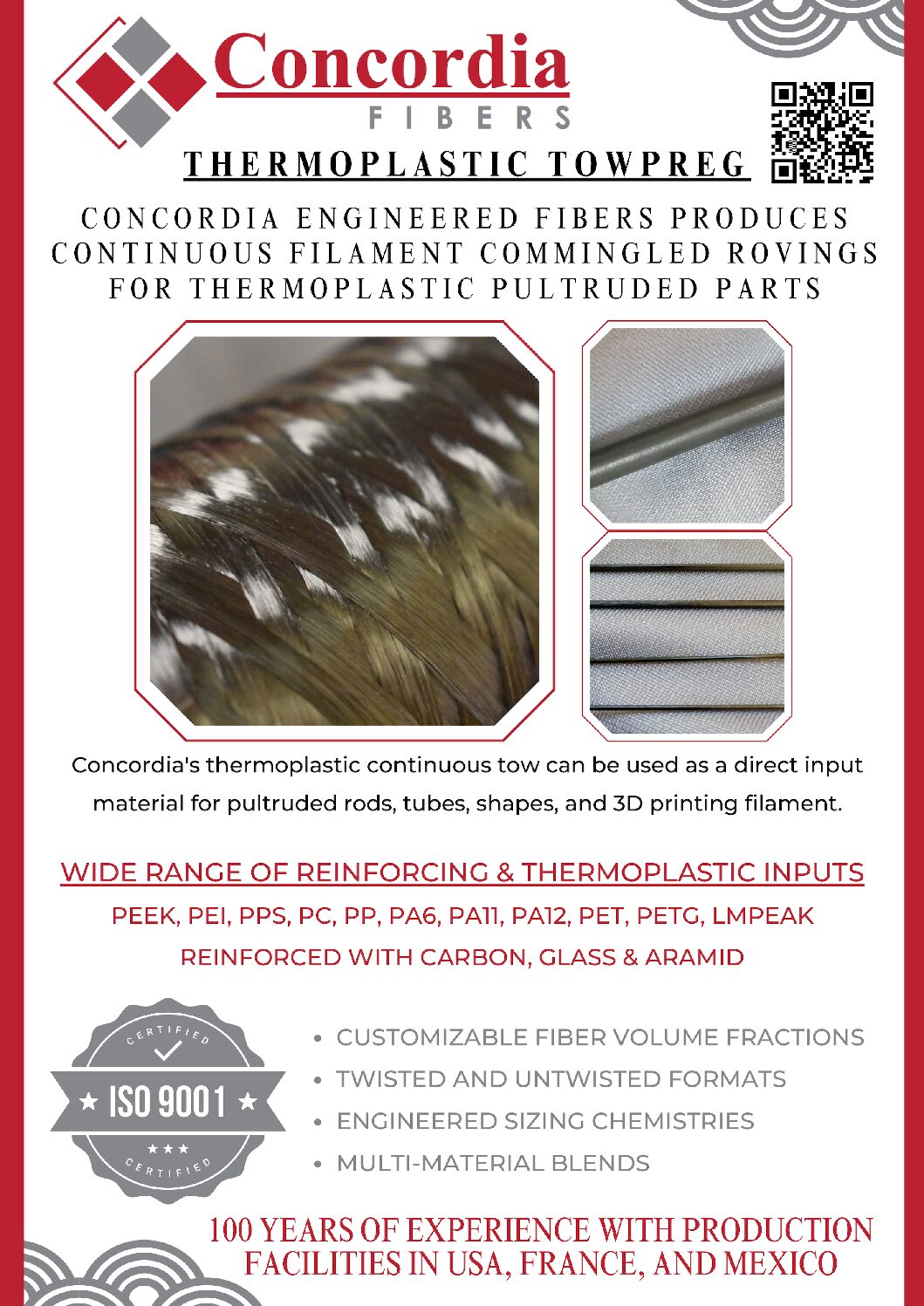

Commingled Fibers

What is commingling?

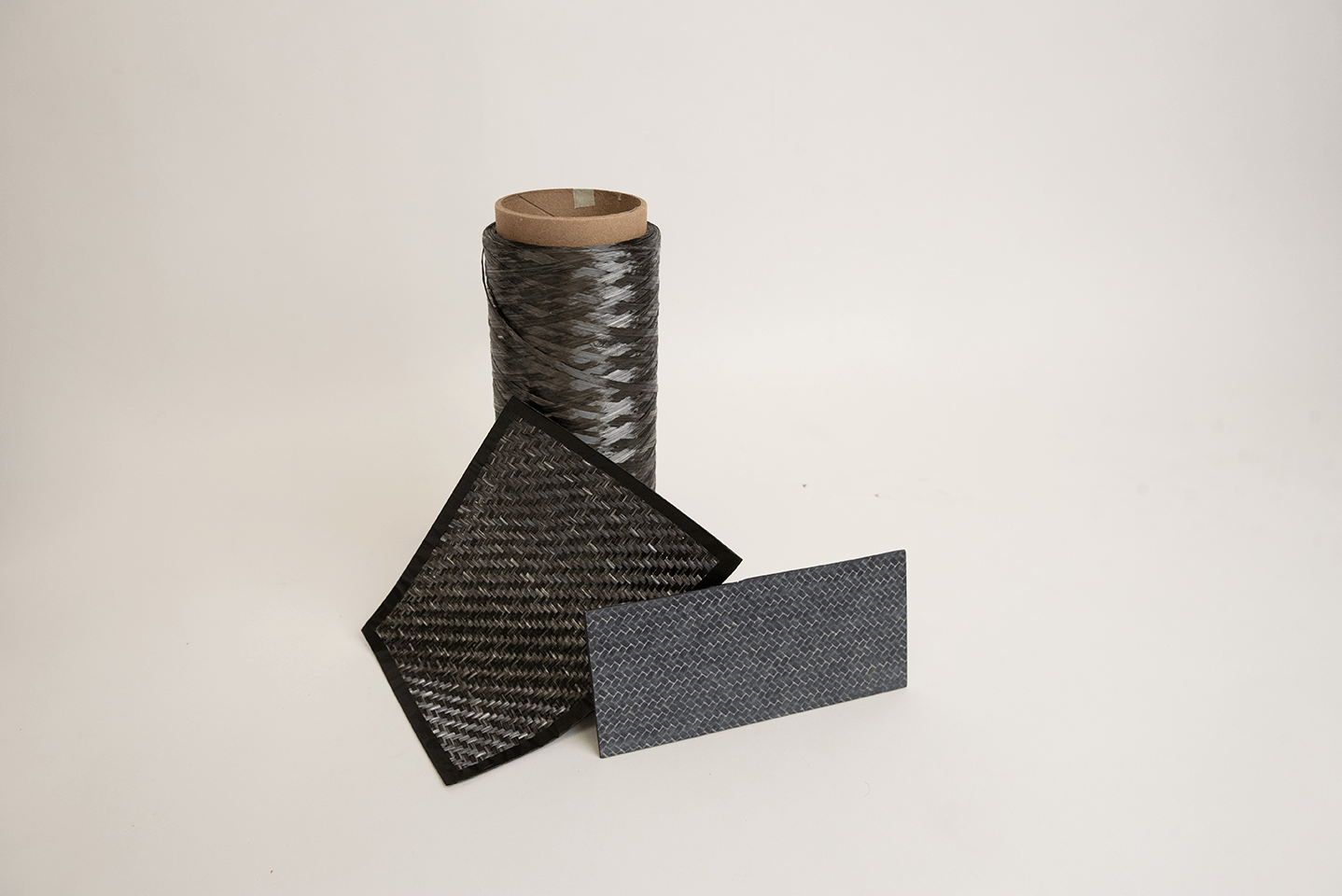

Commingling is a process for producing highly flexible thermoplastic prepregs. Concordia’s unique process intimately blends two or more continuous filament fibers to produce a hybrid homogenized yarn that can be:

- Woven

- Braided

- Knitted

- Embroidered (Tailored Fiber Placement)

- Pultruded

- And More!

Would you like to design your own commingled fiber?

For thermoplastic applications, these formations may then be molded into complex thermoplastic composite shapes when put under heat and pressure.

For thermoset applications, this commingled fiber may be used in any traditional composite process such as Resin Transfer Molding, Prepregging, and beyond.

Commingling Applications

Drones/UAV’s

Structural components which require high stiffness and complicated geometry. Commingled Fiber keeps you flying longer.

Sporting Goods

Greater performance through custom fiber blends. High toughness, high strength, lightweight. Commingled fiber gives you the advantage you need to ace it on the court.

Consumer Electronics

Lightweight with excellent thermal conductivity properties; Commingled Fiber lets you work or play longer.

Request Commingling Guide

Request a Quote

We are excited to engineer a solution to your exact specifications.

Request a sample or quote on a custom order today.